Multi-joint robots, also known as articulated robotic arms or multi-jointed robotic arms, have rotational movement in each joint, resembling the movement of a human arm. They operate with great flexibility, much like a human hand. For instance, when encountering obstacles, a multi-joint robot can maneuver around them to reach its target. It also excels in performing certain specific tasks, such as crank motion, which would be difficult for robots using polar or cylindrical coordinate systems.

Multi-joint robots are one of the most common forms of industrial robots today, widely used across various industries for automation processes. These applications include painting, assembly, welding, handling, packaging, casting, and more, significantly improving production efficiency.

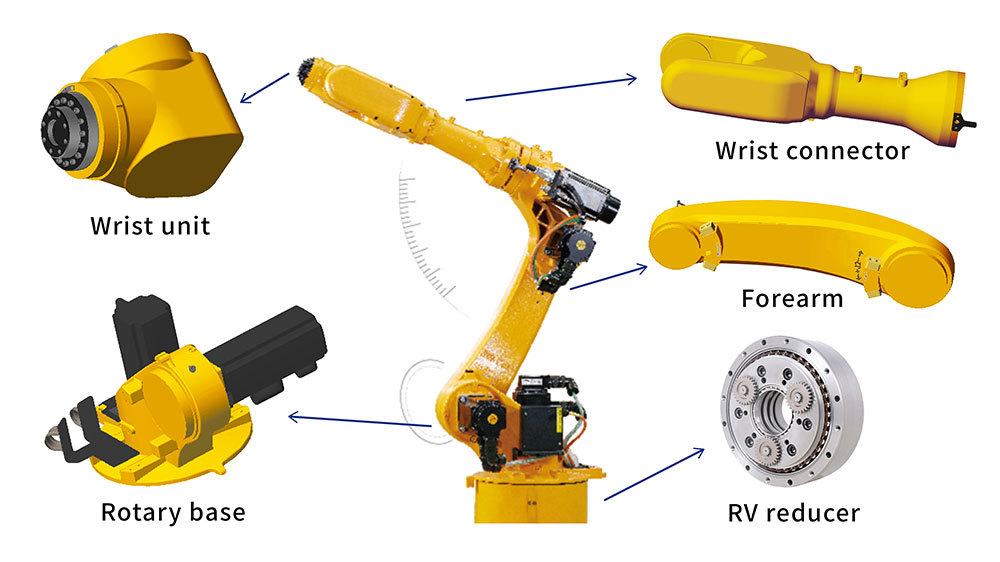

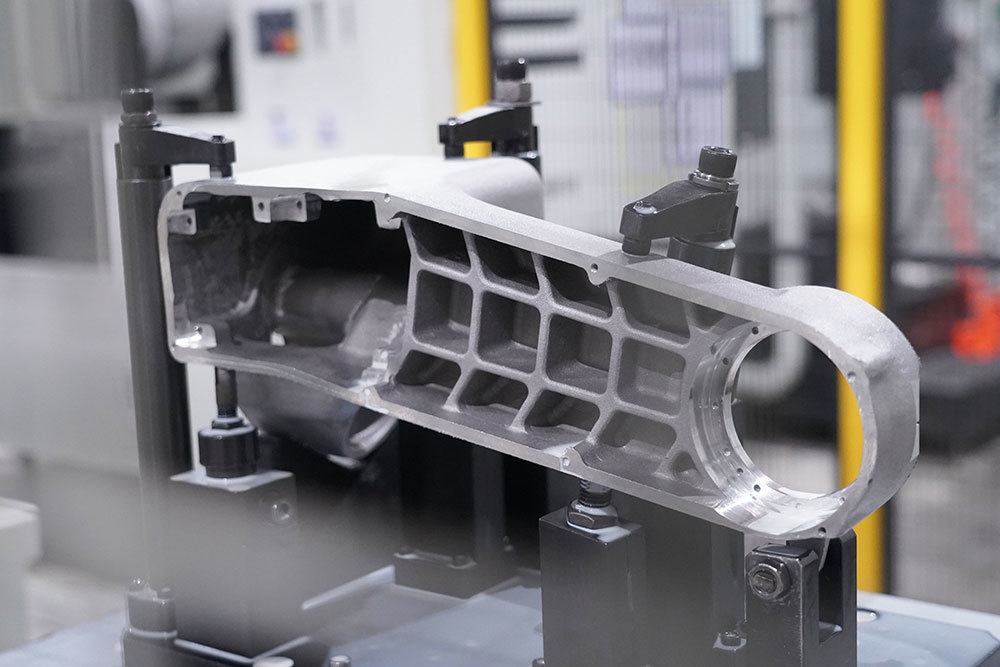

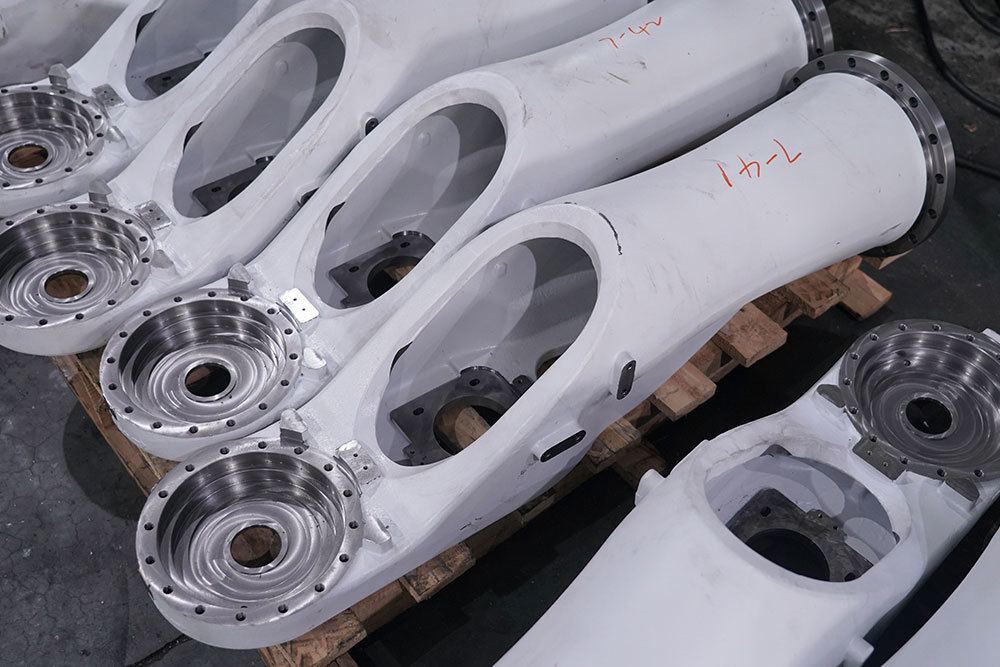

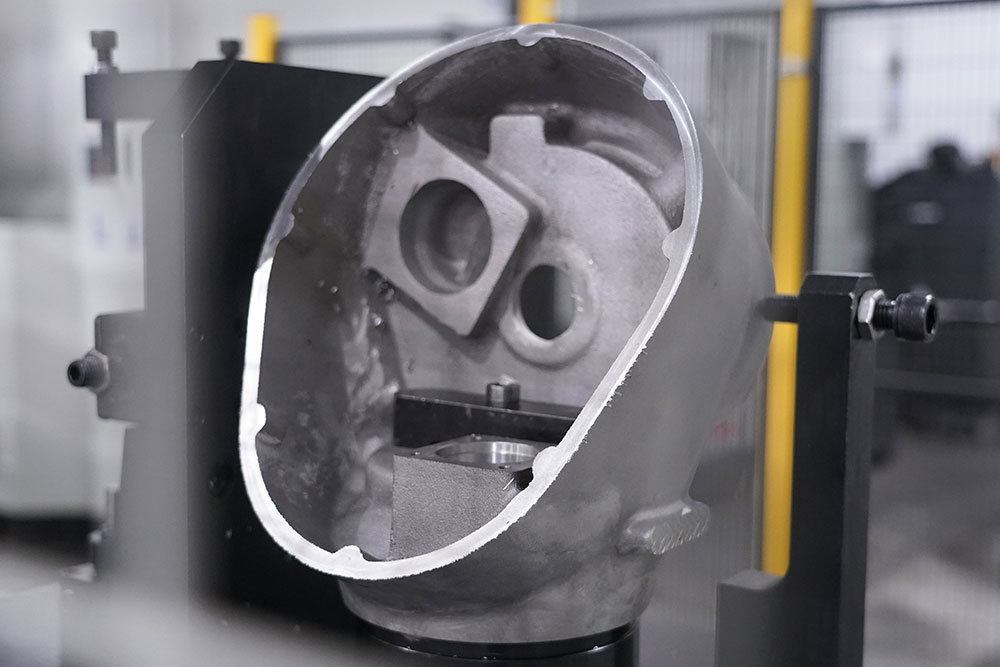

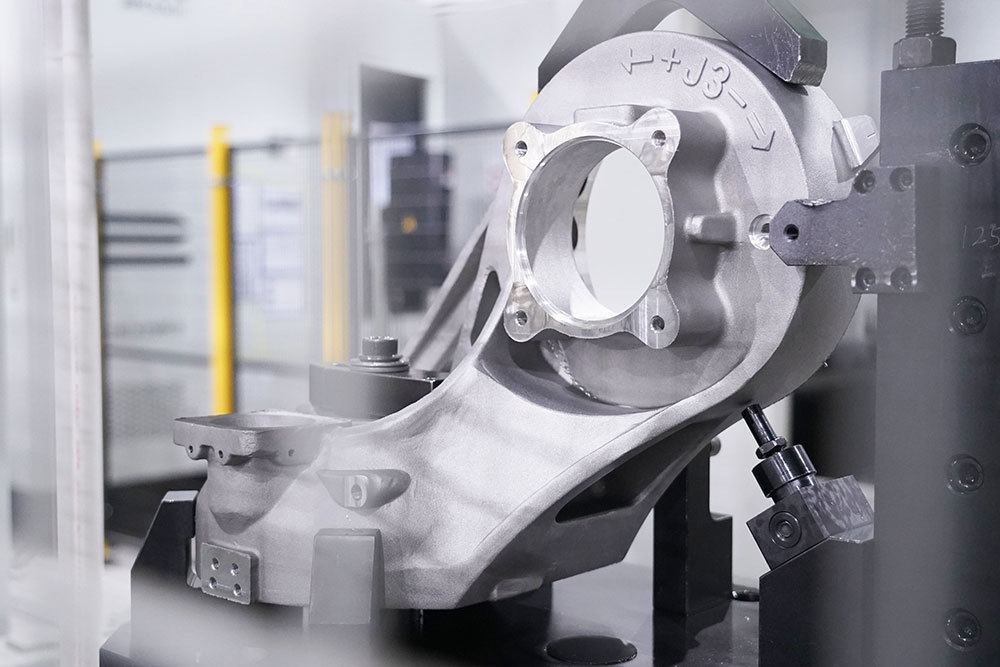

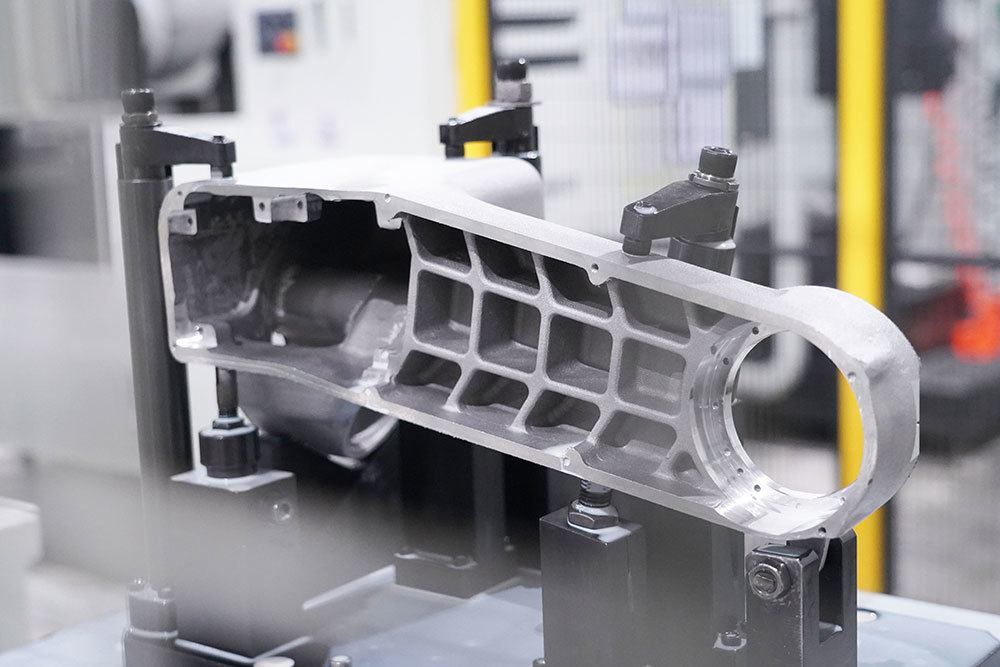

Multi-joint robots typically consist of several joints, offering high precision and speed, ideal for performing repetitive tasks with stringent accuracy requirements. Structurally, they demand compact and lightweight drive components and sensors, with an arm structure made up of wrist units, wrist connectors, forearms, bases, and RV reducers. Some elongated parts, such as wrist connectors and forearms, are particularly well-suited for production using Haitian Precision’s HPC Ⅱ and HUP series horizontal machining centers.

The HPC Ⅱ series horizontal machining centers from Haitian Precision feature a highly rigid base structure, heavy-duty roller guides on three axes, and an integrated high-speed spindle. They can effortlessly handle a wide range of tasks, from high-speed and high-precision operations to heavy-duty cutting, and are compatible with various materials such as aluminum, steel, and cast iron. These machines are widely applied in industries like automotive, aerospace, railways, plastic machinery, and construction machinery for precision machining tasks.

The HUP series horizontal machining centers from Haitian Precision adopt an advanced T-shaped bed structure and vertical spindle box layout, offering strong rigidity and excellent accuracy retention. Capable of machining four sides of a part in a single setup, they are particularly suitable for hole and surface machining in precision-grade box-type components.

As industrial technology continues to evolve, the future of multi-joint robots is set to move toward higher precision, greater speed, increased flexibility, and smarter solutions, with market demand expected to grow rapidly. Haitian Precision will seize this opportunity by continuously upgrading its technology and delivering competitive industry solutions, contributing to the intelligent development of industrial automation and precision manufacturing.

The post Precise Control: Haitian Precision Multi-Joint Robots appeared first on Hision.

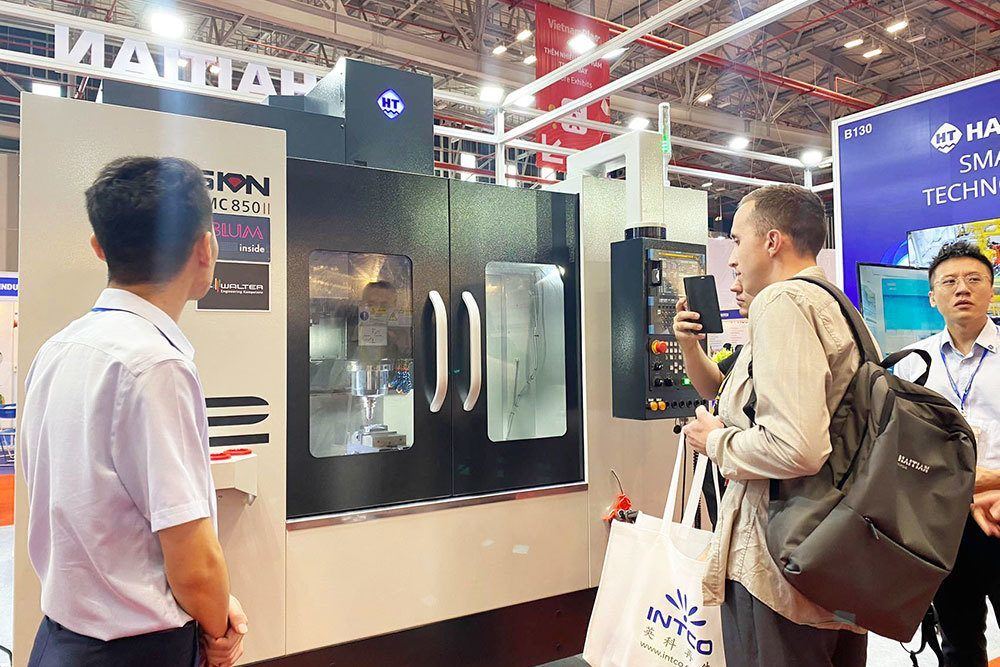

]]>Recently, the highly anticipated 22nd Vietnam International Plastics and Rubber Industry Exhibition kicked off at the Ho Chi Minh International Exhibition Center. This exhibition, one of Vietnam’s premier national-level mechanical industry trade shows, boasts a strong international, professional, and trade focus, attracting 625 exhibitors from 22 countries and regions. The event was full of energy and enthusiasm.

At Haitian’s booth, we showcased not only industry-leading new technological achievements but also introduced sustainable, professional application solutions tailored to the needs of the local market. This drew the attention of international buyers and media, highlighting Haitian’s robust manufacturing capabilities and global influence.

In recent years, Vietnam’s economy has grown rapidly, with its industrial manufacturing sector advancing towards greater intelligence and automation. The demand for smart equipment, including CNC machine tools, has surged. Vietnam’s large domestic market, competitive labor costs and rich natural resources, and strategic location as a Southeast Asian hub offer ideal conditions for the investment and development of industrial manufacturers.

Haitian Precision has been deeply cultivating the Vietnamese market, establishing a 4S Application and Service Center in Bac Ninh to provide faster technical support and high-quality services. We have also set up a spindle repair center to promptly address customer issues, reduce maintenance time, and safeguard customer interests.

Haitian Precision is seizing the chance to expand globally, embracing the world with determination to deliver high-performance, cost-effective equipment and exceptional services to customers worldwide.

The post Haitian Precision’s Further Presence in Vietnam Market appeared first on Hision.

]]>Hunan Zhonggang Intelligent Equipment Co., Ltd. was established in 2021 and is a subsidiary of Hunan Zhonggang Intelligent Manufacturing Co., Ltd. As one of the group’s six major machinery manufacturing centers, it focuses on the R&D and production of intelligent high-end equipment, providing professional supporting services to construction machinery companies. The company has been honored as a national high-tech enterprise, a specialized and innovative SME in Hunan Province, and an intelligent manufacturing pilot enterprise in Changsha.

As the market demands for construction projects become increasingly high-end and intelligent, the construction machinery supporting industry faces unprecedented opportunities and challenges. The cooperation between Hunan Zhonggang and Haitian Precision aligns with these market developments. Recently, we had the pleasure of visiting Hunan Zhonggang and experiencing the spirit of “daring to be first, always striving for excellence” at Zhonggang.

Yue Wenchao, General Manager ofHunan Zhonggang Intelligent Equipment Co., Ltd.

Haitian Precision: Mr. Yue, what is the industry position of Hunan Zhonggang?

Yue Wenchao: Hunan Zhonggang is a key supplier for major domestic projects, construction machinery, steel structure processing, and automotive manufacturing. We are a major distributor of sheet metal and high-strength steel in China and have established long-term strategic supply partnerships with more than 20 large enterprises across the country. Our main business is the processing of general mechanical parts, and some of our products have reached industry-leading levels. Of course, this is closely related to the equipment we use and our quality control. High-quality metal processing equipment ensures excellent product quality.

Haitian Precision: How did you come to know about Haitian Precision and continue purchasing the equipment??

Yue Wenchao: We had heard of Haitian Precision long ago. Haitian Precision enjoys a strong reputation in Hunan, particularly in the construction machinery sector. Both our upstream and downstream suppliers and clients use Haitian equipment. In late 2021, I visited Haitian Precision’s Ningbo factory, where I was impressed by the high-precision equipment and advanced management concepts. Since then, we have continued to purchase Haitian Precision machines, and we currently own seven gantry machining centers.

Haitian Precision: After using our equipment for several years, how would you evaluate it??

Yue Wenchao: With strict quality control and manufacturing systems in place, the quality of Haitian Precision’s equipment is beyond question. We are very satisfied with the products it processes. Additionally, I would like to highlight the continuous stability of Haitian Precision’s equipment. The machines run smoothly and rarely encounter issues, allowing us to focus less on after-sales concerns and laying a solid foundation for long-term production.

Haitian Precision: What are your future development goals??

Yue Wenchao: We are now in the digital age, and Hunan Zhonggang is advancing further into automation and digitalization, accelerating the improvement of production processes and product R&D innovation. We also hope that Haitian Precision can provide more digital solutions for clients like us, helping us enhance cost efficiency, quality, and productivity.

Haitian Precision: What message do you have for Haitian Precision??

Yue Wenchao: Haitian is a national enterprise, and Haitian Precision’s products are of top-notch quality. I hope that more companies, whether at Zhonggang or in our industry, will use Haitian equipment, helping this domestic brand grow and go global.

The post Customer Story: The Pursuit of Excellence in Cooperation appeared first on Hision.

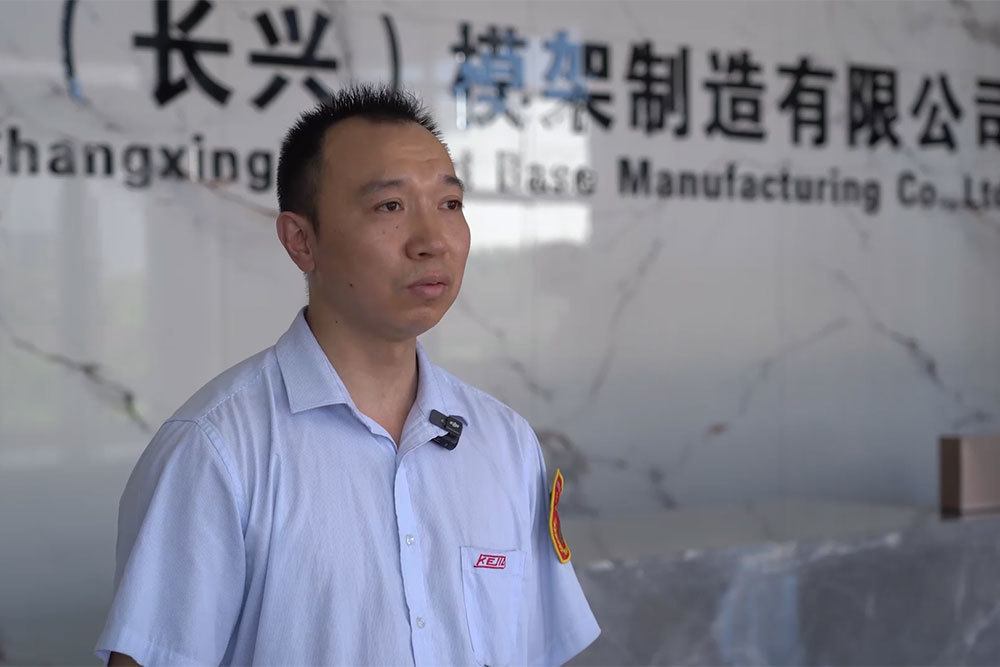

]]>Kejia (Changxing) Mould Base Manufacturing Co., Ltd. (Kejia Mould Base) is a company specializing in the production of die casting mould bases and the sales of mould steel. Established in 1984, the company now employs over 420 people and owns more than 200 CNC machining centers and various processing equipment. Kejia Mould Base has integrated the upstream and downstream production chain, connecting forging, heat treatment, rough machining, and precision machining. It has become a leading large-scale mould base manufacturer in China.

Die casting mould development requires mould base support, as the structure and manufacturing precision of the mould base directly impact the mould’s structure and the precision of forgings. The quality innovation journey between Kejia Mould Base and Haitian Precision began in 2008, with the purchase of the first HTM-1000G, which is still in operation today for rough machining of steel parts.

Kejia Mould Base Deputy Director –?Su Jian

Su Jian, the General Manager of Kejia Mould Base, has deep insights into Haitian Precision’s machines. Over the 16 years of cooperation, Haitian Precision has gained his trust with its strong technical advantages, reliable product quality, and efficient processing capabilities. A stable and reliable partner like Haitian Precision has enabled steady business growth. Currently, 20 Haitian Precision machines are hard at work in Kejia’s new Changxing facility, contributing to Kejia’s growing sales performance.

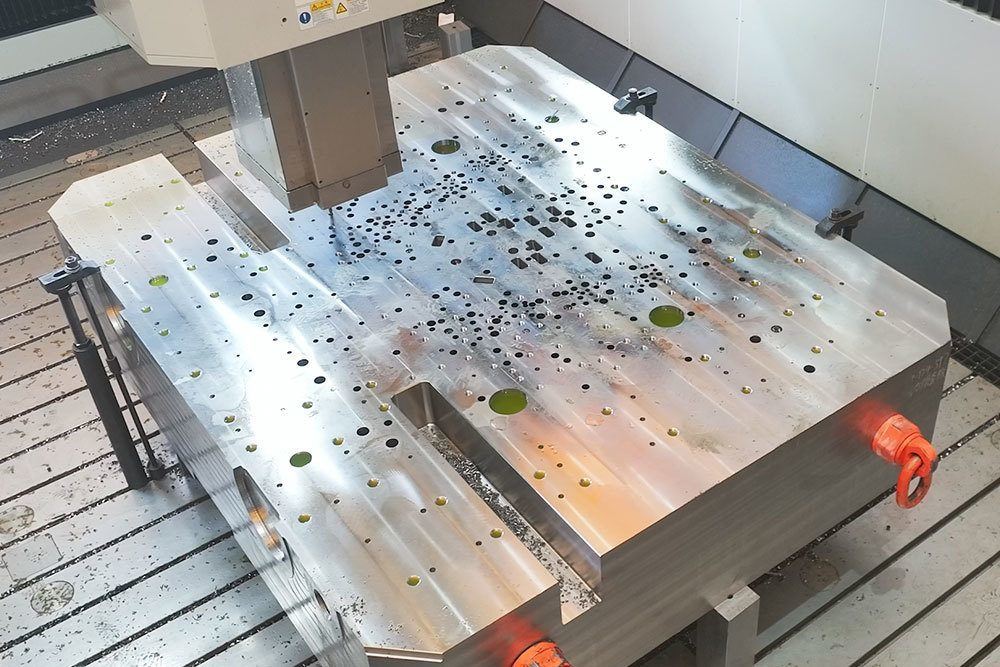

Amid the wave of large-scale die casting, Kejia Mould Base keenly anticipated market trends and was the first to collaborate with a renowned international automotive brand to co-develop the world’s first aluminum alloy die-cast chassis rear axle mould base. This innovation marked a historic breakthrough, reducing the number of components from over 300 parts needing stamping and welding to just three for assembly. Non-standard mould bases have higher commercial value, and this breakthrough also tested the precision and rigidity of Haitian Precision’s equipment.

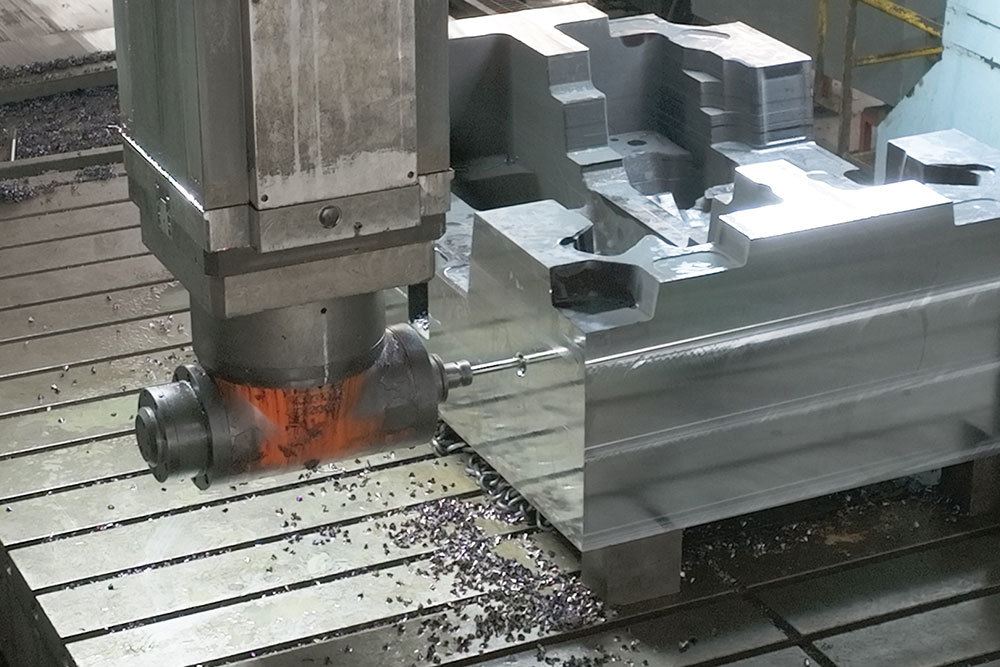

Haitian Precision’s gantry-type five-face milling center excels in high-speed, high-precision machining of complex surfaces, making it ideal for moulds with large surfaces, multi-angle deep cavities, and automotive body panels. At Kejia Mould Base, Haitian Precision’s equipment is used to manufacture mould bases for new energy vehicle front and rear axles, battery boxes, and other components. The side milling head allows for the processing of five surfaces in one setup, and angled cuts can be completed with a single clamping, achieving excellent precision and high surface smoothness. Additionally, after implementing Haitian Precision’s equipment, processing times have been significantly shortened, delivering impressive efficiency.

Production Manager of Kejia Mould Base Yang Kui

“Haitian Precision’s gantry machines are highly rigidincreasing processing efficiency by 30-40% whenworking with materials with a hardness of HRC50-60. “

Kejia Mould Base’s Changxing facility now has the capacity to produce over 3,000 sets of mould bases annually, including over 300 sets of lightweight integrated structural mould bases for new energy vehicles. With rapid business growth, Kejia Mould Base has increased its investment in digitization by introducing ERP, MES, and OA systems to ensure a complete product supply chain, shorten production cycles, and ensure fast delivery. The company is optimizing its smart manufacturing capabilities and deepening cooperation with Haitian Precision to guarantee efficient and stable processing. Currently, Kejia Mould Base has established long-term partnerships with well-known brands such as XPeng and NIO, and plans to further expand into North American and European markets to enhance the global competitiveness and market share of its large-scale mould bases and integrated die-cast mould bases.

In the mould base industry, Kejia Mould Base has won customers over with its technology and quality. We firmly believe that innovation is the driving force behind industrial progress. Whether in traditional industries or new sectors, Haitian Precision continues to innovate and explore the realm of smart manufacturing, playing a key role in every transformation and upgrade in the manufacturing industry.

The post Customer Story: Innovation Drives Integrated Transformation appeared first on Hision.

]]>In the vast blue ocean of smart manufacturing, Estun Automation, a leader in robotics and automation, continuously drives industrial upgrades with its profound technical expertise and spirit of innovation. As a standout in the industrial machine tool sector, Haitian Precision’s high-precision and highly stable equipment is well recognized in the industry. When Estun met Haitian Precision, a deep collaboration in smart manufacturing began, creating a tale of mutual cooperation and integration.

01 Increasingly Seamless Collaboration

Established in 1993, Nanjing Estun Automation (Estun) adheres to an open, innovative, and striving business philosophy, consistently focusing on independent R&D for core technologies. From core components to motion control, and further to robotics and digital intelligent solutions, Estun remains at the forefront of the industry, providing customers with comprehensive smart manufacturing services. Behind this is Estun’s relentless pursuit of manufacturing equipment and stringent quality control over its products.

Encountered with growing production capacity demands, Estun decided to upgrade its overall smart factory solutions by introducing a more efficient Flexible Manufacturing System (FMS). After extensive research and in-depth discussions, Haitian Precision stood out among numerous domestic and international competitors, securing a strategic partnership with Estun due to the high precision of its machine tools and comprehensive technical support.

As the equipment gradually arrived and was installed and debugged, the teams from both sides worked closely to continuously optimize production processes, ensuring each step achieved its best state. Since its launch at the beginning of the year, Haitian Precision’s FMS has been running stably, with production steadily increasing, proving the correctness of Estun’s choice.

02 A Dual Leap in Efficiency and Quality

Haitian Precision’s FMS focuses on the precision machining of motor housings, drive casings, robot bases, and arm castings, bringing significant efficiency improvements to Estun. The introduction of FMS allows for zero-changeover and zero-switching when processing various complex robot components, significantly enhancing equipment utilization. At the same time, Haitian Precision’s high-precision machine tools ensure that the machining accuracy meets or even exceeds expectations, laying a solid foundation for Estun’s product quality.

Haitian Precision’s FMS has effectively improved Estun’s production and processing model. In terms of manpower, what once required one person per machine now only needs one to two people to manage six machine tools in continuous operation, greatly increasing processing efficiency. Additionally, the flexible line’s built-in tool breakage monitoring function can automatically switch tools using sister tools, protecting tool life and reducing downtime. The multiple sets of process programming within a single machine can automatically select processing based on the loaded workpieces, offering distinct advantages over traditional gantry lines or robots in the production of small batches of diverse products. The high-precision horizontal machining centers from Haitian Precision also demonstrate outstanding performance, running stably and meeting both high-load cutting and high-speed processing needs, fully maximizing efficiency.

Assistant to the President of Estun: Li Wenlong

“FMS has further enhanced production operatingrates, reaching a high level of 90%-95%. The preci-sion is also spot-on, with daily part accuracy within10 microns, fully meeting production requirements.”

03 Comprehensive Support and Assurance

Estun highly praises Haitian Precision’s machineries, believing that it matches or even surpasses foreign brands in performance. Haitian Precision’s technical support and after-sales service have provided Estun with unprecedented convenience and peace of mind. The technical personnel at Haitian Precision are not only professional and responsible but also proactively analyze and eliminate potential risks after resolving issues, preparing preemptive plans to ensure the continuous and stable operation of the production line.

Haitian Precision understands the importance of after-sales service, from equipment installation and debugging to daily maintenance. Their technical application personnel are always by their side, ensuring the equipment is always in its best state. Additionally, Haitian Precision has provided customized services tailored to Estun’s production needs for robot part machining, further improving production efficiency and machining accuracy.

Chief Engineer of Estun: Zhang Haicheng

“Haitian Precision has given Estun strong supportin technology and services, and their guidance hasbeen of great help to our equipment staff.”

As emerging industries continue to seek both “new” in “quality”, Estun and Haitian Precision have formed complementary advantages in the industrial chain, bringing about mutual understanding and synergy. Intelligent matching allows the machine tool’s performance to be maximized, while the machine tool ensures efficient and stable production of parts. High-end CNC machine tools and smart equipment are setting a new benchmark for the industry, opening up new boundaries in smart manufacturing. The story of Estun and Haitian Precision in this manufacturing revolution continues…

The post Customer Story: Innovative , Boundless Smart Manufacturing appeared first on Hision.

]]>With a refreshing autumn breeze and clear skies, Haitian Precision successfully hosted a unique Global Open House in Ningbo, demonstrating its exceptional innovation capabilities and forward-looking technological vision. A colossal number of partners and clients from across the country gathered to witness the brilliant emergence of a new era in smart manufacturing.

At the event, several meticulously prepared new products from Haitian Precision made their debut. These products are not only a perfect blend of market demand and technology but also a precise grasp of industry development trends. Characterized by high stability, rigidity, efficiency, and precision, these products cover a wide range of manufacturing fields, from aerospace and rail transportation to automotive parts, mold making, precision machining, and structural component processing, providing robust support for the transformation and upgrading of various industries.

In addition to mainstream products, new launches such as the HBM110 CNC horizontal boring and milling machine, MOV850 vertical machining center, and HF18 horizontal machining center captured the attention of attendees. They listened intently to the explanations from professional technicians, expressing high praise for the innovation and reliable quality of the products.?

Further performance upgrades were made to several models, including the VMC850HS PLUS high-speed vertical machining center, HA80II horizontal machining center, and GRU32IIx40 gantry machining center. These enhancements align with current industry development needs, fostering high-quality growth in the sector.

A truly excellent product must solve real customer problems and meet genuine market demands. Haitian Precision continuously explores technological boundaries and keenly observes market needs. Through ongoing product upgrades and optimizations, the company injects a steady stream of power into the flourishing development of the manufacturing industry.

The post Haitian Precision Global Open House Successfully Held appeared first on Hision.

]]>From August 10-12, Haitian Precision hosted a factory open day at its Ningbo facility. Over 50 guests from regions including Mexico, Brazil, India, Indonesia, the United States, Saudi Arabia, and Pakistan attended the event, experiencing firsthand Haitian’s robust manufacturing capabilities and the advanced technology and products of Haitian Precision.

Accompanied by staff, guests toured the Haitian Digital Experience Center, gaining a comprehensive understanding of Haitian’s development history, industry layout, intelligent manufacturing, global strategies, and corporate culture. They also visited the Haitian Precision Yanshan and Dagang factories.

On-site displays covered solutions for industries such as automotive parts, molds, precision machining, structural components, and aerospace. Professional technicians explained the machine features to the guests, while experienced application personnel provided cutting trial solutions. The guests were fully engaged, taking photos and expressing high praise for Haitian Precision’s products.

In addition to the Haitian Precision facilities, the guests also visited the Haitian Plastics Machinery Dagang Intelligent Factory and the Haitian ZhiSheng Metals Bonded Area Factory. A series of advanced production equipment and highly intelligent production processes left a deep impression on the visitors, challenging their perceptions of traditional manufacturing and allowing them to experience Haitian’s powerful manufacturing capabilities up close.

The factory open day provided a platform for communication and exchange among international partners, customers, and industry peers. It showcased Haitian Precision’s advanced processes, innovative technology, and products, fostering mutual understanding and creating opportunities for further cooperation. Looking ahead, Haitian Precision will continue to uphold its customer-first philosophy, providing more heartfelt products and services to users worldwide.

The post Haitian Precision Ningbo Factory Open Day Successfully Concludes appeared first on Hision.

]]>The GU HS Series Gantry Machining Center from Haitian Precision embodies the traditional gantry features of strong rigidity, symmetrical structure, and high stability, offering a variety of specifications to meet market demands with table widths ranging from 700mm to 1500mm. This series further highlights the advantages over traditional C-type vertical machining centers, enhancing cutting performance and providing a new experience for customers. The product is suitable for fields such as construction machinery, automotive parts, molds, and plastic machinery. Its exceptional chip rigidity, efficient metal removal rate, and stable and reliable machining accuracy are its core strengths.

Expanded Machining Range? The Z-axis travel of the entire GU HS series has been increased to 800mm, and both the gantry width and Y-axis travel have been enhanced.

Powerful Cutting Capability? The entire series is equipped with high-rigidity cross hard rail rams, ensuring the rigidity and anti-vibration needed to fully utilize the high-torque performance. The integrated structure of the beam and column reduces contact surfaces and error accumulation, enhancing reliability and stability.

All transmission components are self-made, with a full-gear transmission gearbox for quick and convenient shifting, smooth rotation, and low noise.

Haitian Precision’s self-developed high-torque mechanical spindle offers a maximum speed of 6000rpm, a maximum torque of 520Nm, and a 6+1 bearing arrangement, ensuring strong cutting without vibration, suitable for heavy-duty machining. The spindle features a mechanical safety lock for safer tool changes.

Rich Optional Features? The HS ram is pre-equipped with an automatic head interface. In addition to the manually adjustable head, it also offers an optional BT50 automatic right-angle head.

Intelligent Module Upgrades? Secondary development of the system software makes the product smarter, with features like parameterized workpiece adaptive function, visualized tool load monitoring, simplified processing condition selection, and digitized operation monitoring. Additionally, a spindle thermal compensation function can be added to ensure stable machining accuracy.

Flexible Automated Production Line? ?The main machine offers a wide range of automated production line configuration options, suitable for producing various parts from small batches to medium-large batches, making factory automation easy to achieve.

Heavy Cutting (Cast Iron)

Tool: Φ125 Face Mill

Material: HT200

Speed: 450rpm

Cutting Width: 100mm

Cutting Depth: 8mm

Feed Rate: 800mm/min

Tapping (Cast Iron)

Tool: M42x2 Fine Thread Tap

Material: HT200

Speed: 150rpm

Cutting Width: 2mm

Cutting Depth: 65mm

Feed Rate: 300mm/min

Heavy Cutting (Steel)

Tool: Φ125 Face Mill

Material: 45#

Speed: 450rpm

Cutting Width: 100mm

Cutting Depth: 6mm

Feed Rate: 783mm/min

Tapping (Steel)

Tool: M42 Coarse Thread Tap

Material: 45#

Speed: 114rpm

Cutting Width: 4.5mm

Cutting Depth: 65mm

Feed Rate: 513mm/min

Heavy Drilling (Steel)?

Tool: U98 Drill

Material: 45#

Speed: 330rpm

Cutting Width: 98mm

Cutting Depth: 150mm

Feed Rate: 50mm/min

Boring (Cast Iron)

Tool: Φ320 Boring Tool

Material: HT200

Speed: 200rpm

Cutting Width: 8mm

Cutting Depth: 80mm

Feed Rate: 40mm/min

Boring (Steel)?

Tool: Φ320 Boring Tool

Material: 45#

Speed: 200rpm

Cutting Width: 6mm

Cutting Depth: 80mm

Feed Rate: 32mm/min

The post Hardcore Innovation: GU HS Series Gantry Machining Center appeared first on Hision.

]]>Keda Industrial Co., Ltd. was established in 1992, focusing on building materials machinery, overseas building materials, and lithium battery materials and equipment. Its products are sold in over 70 countries and regions, making it a global leader in ceramic machinery. This issue of Haitian Precision takes you into Keda Industrial’s wholly-owned subsidiary, Foshan Keda Equipment Manufacturing Co., Ltd., to showcase the impressive performance of large gantry machining centers in structural part processing.

Keda Equipment’s smart manufacturing base in Sanshui District, Foshan City, officially started operations earlier this year. This new base is an advanced work following the introduction of extensive digital smart technology and hardware facilities by Keda Equipment. The base adopts a one flow & one-stop model, allowing large structural parts to undergo continuous operations from cutting and welding, annealing, primer sandblasting, machining, to final painting and shipment. The one-stop model ensures that the entire process for large structural parts is completed within the factory.

The first phase of Keda Equipment’s smart manufacturing base covers 100 thousand SQM, with four production workshops. Thanks to high investment, the plant has an underground drainage system, hardened roads with “four horizontal and two vertical” layout, full pile foundations, and high factory heights. These provide a comfortable working environment for employees and optimal conditions for machine cooling, ventilation, and smoke exhaust.

Zhou Guosheng, Keda Equipment General Manager

“Looking back, choosing a single equipment provider brought us better service. Haitian Precision’s gantry machines meet our expectations in terms of machining accuracy and stability.”

When discussing the new base, Keda Equipment General Manager Zhou Guosheng exudes confidence: “Our factory is embedded with a lot of digital genes. All the Haitian equipment we purchased is equipped with IoT cards, creating a naturally digital factory through interconnection.”

Keda Equipment provides key front-end component processing for its headquarters. In Zhou Guosheng’s view, both Haitian and Keda Equipment solidify the industrial foundation through their front-end manufacturing processes. As industry leaders, Haitian Precision has been Keda Equipment’s top choice from the beginning.

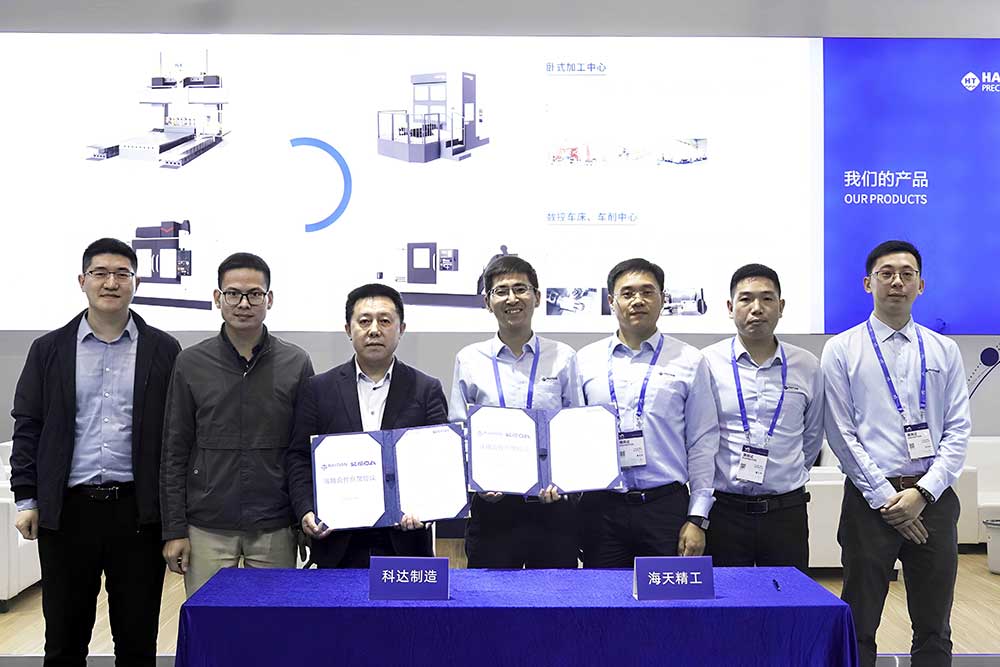

2023 Shenzhen Exhibition Signing Ceremony

Early last year, Keda Equipment signed a contract for 15 large machining centers from Haitian Precision. Zhou Guosheng recalled, “When building this factory, I visited nearly 200 factories across the country, including almost all equipment manufacturing plants in South China. Our facility is the largest gantry machining center cluster in South China.” From installation to commissioning and from production ramp-up to stable production, Haitian Precision provided meticulous service, ensuring strict adherence to the production schedule.

In Workshop No. 3, 15 large gantry machines from Haitian Precision range in size from 8 to 18 meters, featuring strong rigidity, high power and torque, and high stability. They are primarily used for large structural parts such as frames and beams, including large cast and forged parts. All gantries are equipped with the latest system versions, offering user-friendly programming tailored to Keda Equipment’s commonly used parts, saving time and facilitating employee operation during busy work conditions.

The innovative dual gantry machining center further enhances efficiency and is user-friendly for operators, allowing one employee to operate two machines simultaneously, significantly speeding up production. This novel custom equipment serves as a reference model for large structural equipment manufacturing enterprises.

In the new era, supply chains and industrial chains require resilience. Zhou Guosheng is acutely aware that to go further, enterprises must strengthen their foundations and solve critical problems. He mentioned that Haitian Precision’s side milling heads and boring heads break monopolies. When boring deep holes, Haitian Precision’s tools can penetrate thin areas, reducing vibration and improving machining accuracy. Keda Equipment aligns with Haitian Precision’s self-made and self-produced core components, controlling key processes to ensure sustainable accuracy. Keda Equipment continuously promotes technological innovation and iteration of new technologies, driving production capacity to land on its “go global” path.

As Keda accelerates its global expansion and deepens its global layout, Keda Equipment contributes foundational strength. With the increasing share of overseas sales, Keda Equipment has configured a large number of exports, providing related support services for the headquarters and export enterprises. This is also an inevitable trend for healthy and sustainable corporate development. Zhou believes that front-end manufacturing enterprises need to address their shortcomings and possess independent technology to avoid external constraints, thus realizing “China Intelligent Production”.

Keda Equipment’s development reflects the pursuit of manufacturing enterprises for research and development, innovation, and exploration. Guided by the business philosophy of “innovation has no end”, Keda Equipment, along with Haitian Precision, will accelerate the pace of intelligent manufacturing, adding new momentum to the development of the equipment manufacturing industry in South China and beyond.

The post Customer Story: Elevating Quality Through Innovation appeared first on Hision.

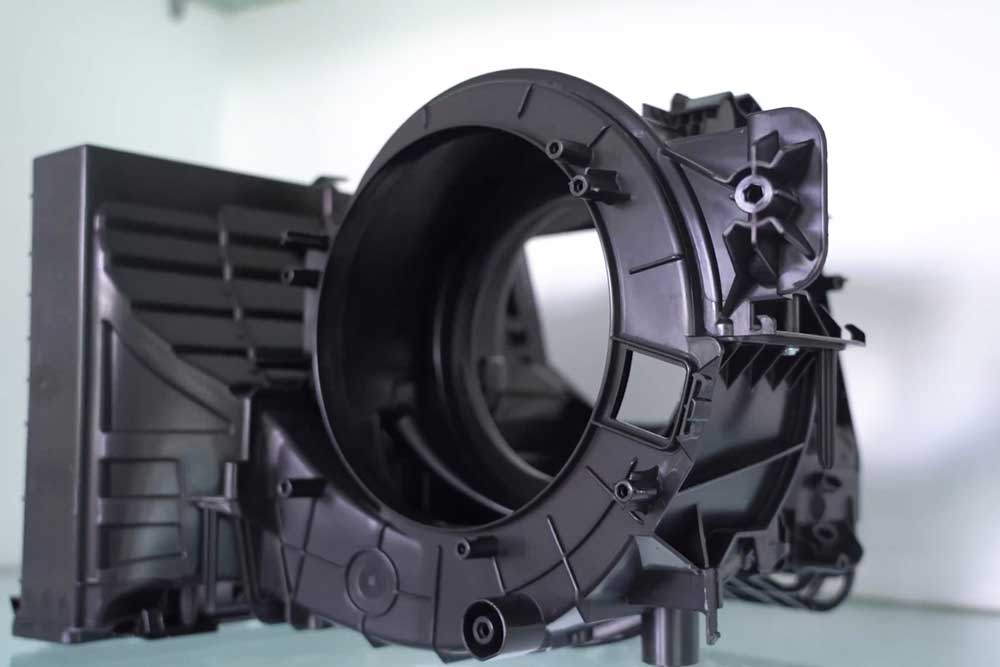

]]>Ningbo Huazhong Mold Manufacturing Co., Ltd. (Huazhong Mold) is a wholly owned subsidiary of Huazhong Holdings. It is a technology-based enterprise specializing in the research and production of automotive parts and plastic injection molds. Established in 2002, the company currently has more than 190 employees, with over 25% being mid-to-senior technical R&D personnel and boasts a wealth of skilled talent. This issue of Haitian Precision takes you inside Huazhong Mold to witness the rapid development of automated production via human-machine integration.

The relationship between Huazhong Mold and Haitian Precision dates back to 2004 when Huazhong Mold purchased its first 850G machining center, marking the beginning of a long-lasting partnership. As one of the earliest domestic clients of Haitian Precision, Huazhong Mold has the most say in the matter. General Manager Zhou Huajiang of Huazhong Mold couldn’t hide his admiration when mentioning the 850G, noting that the twenty-year-old equipment still reliably performs rough and semi-finish machining tasks, laying the foundation for subsequent cooperation.

Zhou Huajiang explained, “The application personnel from Haitian Precision Machinery showed us the automated line for standard parts and planned a tailored solution for us, which I found aligned with my ideas. Mold part processing is very different from standard parts. From discussing the plan to introducing the automated line, we went through many rounds of adjustments, including continuous improvements and optimizations after the line arrived at the company. It is now successfully in production, meeting my expectations.” This step taken by Haitian Precision and Huazhong Mold provides a replicable template for the digital, low-cost, and high-efficiency development of mold enterprises.

In the production workshop of Huazhong Mold, we saw the FMS automatic line, which consists of four Haitian Precision CFV1100 vertical machining centers, along with loading and unloading stations and AGV carts, enabling an “8+16” intelligent manufacturing mode. The production line operates with minimal human intervention for 8 hours during the day, handling loading, clamping, and inspection tasks, while running unmanned for 16 hours at night, significantly boosting production efficiency.

Chen Guangzeng, Manager of the Processing Department at Huazhong Mold

Chen Guangzeng, manager of the processing department, jokingly said, “The automatic line has solved the problem of employees unwilling to work night shifts and young people unwilling to enter factories.” He explained, “This automatic line realizes functions such as automatic tracking, automatic correction, automatic edge detection, and automatic tool setting. Previously, operators had to manually set electronic levels and re-align each tool, which was time-consuming. Now, these issues are resolved through probes and automatic macro programs, avoiding human errors.”

Additionally, Chen Guangzeng introduced the Haitian Precision DFS3020 five-axis high-speed milling center in the workshop, which addresses the issues of multiple electrodes and long spark cycles, enabling small tool corner clearing and reducing electrode processing by over 90%. It has been running steadily for six years, with swing angle accuracy maintained at around 0.02mm, performing exceptionally well.

Additionally, Chen Guangzeng introduced the Haitian Precision DFS3020 five-axis high-speed milling center in the workshop, which addresses the issues of multiple electrodes and long spark cycles, enabling small tool corner clearing and reducing electrode processing by over 90%. It has been running steadily for six years, with swing angle accuracy maintained at around 0.02mm, performing exceptionally well.

The post Huazhong Mold: Human-Machine Collaboration Creates a New Engine for Smart Manufacturing appeared first on Hision.

]]>